FM staff sew face coverings

Employees get creative to boost the department's supply of PPE

We are highlighting different Facilities Management teams and their work to serve the University throughout this challenging time.

Facilities Management employees are working creatively to ensure the department has an adequate supply of cloth face coverings.

“[Face coverings] are hard to come by,” said Specialty Trades Supervisor Senior Warren Wood. “I got to thinking how we have a sewing machine in our shop.” The machine is typically used to repair banners and upholstery. “I told Mark [Stanis] we can probably make some of these [face coverings] if we can get the material.”

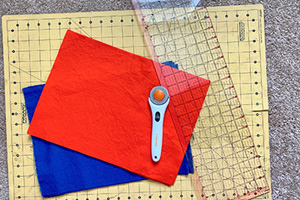

Wood obtained material from the Walmart fabric department and tasked Trades Utility Senior Worker Carl Shifflett with the job of sewing together the face coverings. “I started by making one out of a paper towel to make sure it was a good fit,” explained Shifflett, who followed a design provided by the Centers for Disease Control and Prevention (CDC) which recommends using a double layer of 100% cotton.

Shifflett has made a total of 250 face coverings as of April 16, with the goal of creating 500 to 1,000 over the next few weeks. The face coverings will then be provided to the FM Logistics division who is handling the distribution of these items to FM staff members through a request process.

The CDC now recommends face coverings in public settings where other social/physical distancing measures are difficult to maintain. Any FM employee needing to work within six feet of another individual to complete their job or task must wear fabric or paper face coverings, according to Occupational Health & Safety.

“In order to protect myself and others from the spread of COVID-19 I have been wearing a cloth face mask while around construction personnel on construction sites,” said CC&R Project Coordinator Sam Walker. “It has been very helpful to have since there is a shortage of this type of PPE….I would like to thank Carl for all his hard work in sewing and providing these cloth face masks for Facilities Management personnel.”

In addition to the Sign Shop’s efforts, FM Technology & Innovation staff members User Experience & Engagement Manager Jennifer Watson and Multimedia Designer Avery Wagner have been sewing cloth face coverings at home using their personal sewing machines. They are using high-quality, 100% cotton with micro para cord and cord locks in place of elastic, which is in short supply. These face coverings will also be provided to the Logistics division to distribute to FM staff members.

Jane Centofante

Communications senior generalist

UVA Facilities Management

(434) 982-5846

janecentofante@virginia.edu